When needing to create a temporary or permanent barrier in a well to seal off or isolate a chosen section downhole, inflatable Bridge Plugs are the go to tool! Used predominantly in oil and gas applications to block off unwanted flow from a reservoir or for well abandonment and decommissioning projects.

Usually inflatable Bridge Plug packers are run in on drill pipe to a predetermined depth and inflated to a high pressure with water via the drill rods. This sets the plug in place within the casing or open hole. The drill string can then be disconnected from the plug via a left hand back off sub or shear-pin mechanism. Inflation pressure is maintained in the plug, via one way check valves that are set off at increasing pressures in the packer’s inflation assembly.

Now firmly in position grout can be pumped on top of the bridge plug and set creating a cement plug, providing a permanent barrier for well abandonment. If a section downhole requires only temporary isolation RIPE also manufacture retrievable bridge plugs. The inflation assembly in a retrievable bridge plug provides two way sealing, allowing the operator to equalize pressure in the packer before deflating. Bridge Plugs can also be made from drillable components, so that after a cement plug has been set the hole can easily be re-drilled.

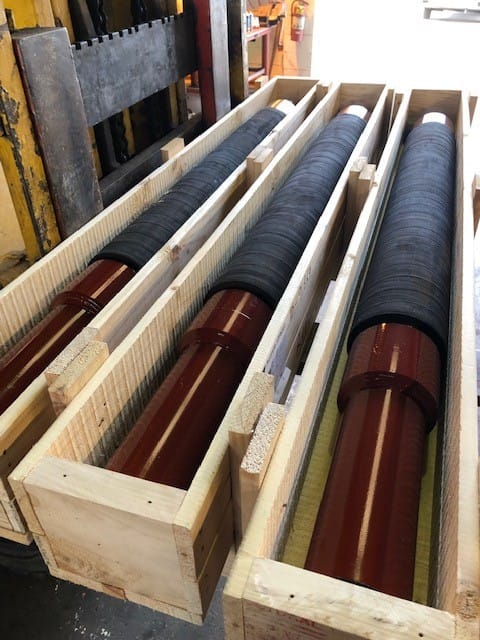

Aimed at performing the required task of decommissioning bores, either temporarily or permanently, we construct a range of inflatable bridge plugs used across the water, mining, oil and gas industries.

Testimonial

“John, Your first Bridge Plug that we set at 1250 meters inside 7 inch casing, went very well with no problems. We ran the 3-1/2 inch Bridge Plug into a deviated cased hole 5-1/2 inch casing to around 1500m. Set the Bridge Plug and disengaged. All went well again.”

Lou DeVattimo

Oil Drilling and Exploration

Kimberley’s Well Decommissioning Project